|

|

|

|

I'm learning the art (or is it a craft?) of stained glass. At this weblog, I record progress, note useful links, and document flesh wounds. Links

The Art League

Weisser Glass Studio

Virginia Stained Glass Co.

Warner-Crivellaro

Glass Galleries Links List

The StoreFinder: Stained Glass Store Front

ArtGlassArt.com Tutorials

rec.crafts.glass

Nancy's Beginner Tips and Tricks

Splinter Removal Tips

Syndicate this site

Archives

By Date

December 2006 November 2006 October 2006 May 2006 June 2004 October 2003 September 2003 August 2003 June 2003 May 2003 April 2003 March 2003 February 2003 January 2003 December 2002 November 2002 October 2002 September 2002 By Project Beaded Unity Candle Crocus Panel Dogwood Windows Green Tiered Lamp Lilypads/Lotus Panel Transoms Xmas Ornament |

|

Friday, December 08, 2006: We Have The Technology

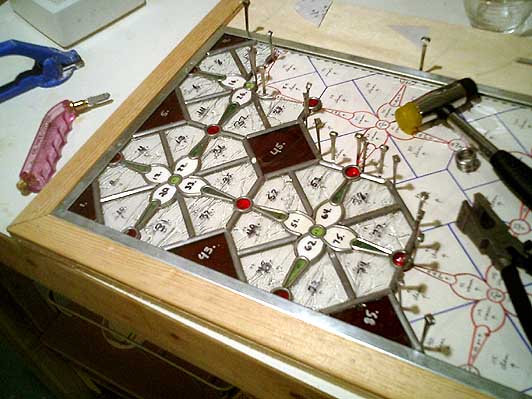

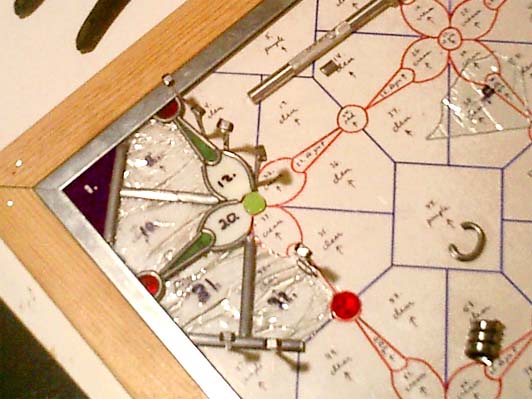

My big old brick of a digital camera wasn't broken! Instead, it was the card that was bad. In technical terms: it went kerflooey. Celebrate with me, won't you? Herewith: a few up-close-and-personal photos of dogwood window #1---now 30% leaded---for no reason other than that I could.

Posted by Michelle at 05:24 PM

| Comments (7)

Monday, December 04, 2006: Stolen Time

Why is it that every time I get really grooving on a stained glass project, every client I've ever had comes out of the woodwork needing me to write code for them? For the last week, I've been sneaking down to the basement to do ten minutes at a time of leading. "Oh, I have to, uh... check the laundry. Right! Down to the basement I go, la di da..." You can get a decent amount accomplished this way. Denial is your friend.

I now have approximately 28% of the first panel leaded. Fitting in that big red-purple diamond in the middle felt good, let me tell you. Notes to self: never ever again buy Spectrum 100K crackle glass. The ripply veins of texture are so pronounced that they make the glass thicker, in places, than you can fit into a lead came channel. So I've been having to use my grinder in ways that this particular grinder was never meant to be used. I always wondered what was the point of a disc grinder. Now I know. Also, the mystery Wissmach glass I'm using for my flower petals has a texture problem all its own. Both sides are very finely stippled, as opposed to the mirror-smooth finish on the "cutting side" of Spectrum glass. This makes cutting slightly tougher on the Wissmach, but not enough to be a big pain. No, the big pain is trying to get spray adhesive off the Wissmach, an experience that I imagine is similar to trying to get bubble gum off of concrete. I don't know how much time I'll have left to steal for the rest of this month. For every item I cross off my to-do list, two more arise to take its place. As for Christmas, I'm pretending it doesn't exist. I don't have time for so much as a bah humbug. Although we did break out the red-velvet-and-white-fake-fur Christmas jingle collars for the dogs the other day, and watching Polar spin alertly in circles, wearing his collar and trying to figure out where the noise was coming from was, I'll admit, pretty darned festive. Posted by Michelle at 10:24 PM

| Comments (1)

Sunday, November 26, 2006: Proof-of-Concept

Saturday, November 25, 2006: Anal-Retentives Apply Within

A couple of days ago, I began the process of faux-laminating my cutting pattern with Mylar and spray adhesive, and then the actual cutting. It's tedious work, not to mention sticky, and I didn't get too far before telling myself that I really needed to know that the laminated and cut pieces would hold up on the grinder before going so far as to cut out all 230-odd pieces. So I located the first couple of pattern pieces according to building order, and cut some glass accordingly. Indeed there were a couple small process kinks to work out there, having to do with the need to spray pattern pieces and glass, then let them sit for a couple of minutes to partially air-dry before putting the two together, for maximum stickiness. With previous projects my pattern pieces have been just plain paper, affixed with glue sticks, but the combination of glue stick and Mylar just makes a slippery mess that slides around all over the place on the grinder. And actually, about the same thing happens if you try to slap together a Mylar-ed pattern piece and some glass immediately after applying the spray adhesive. So I got that all worked out, and thought about laminating and cutting the rest of my pattern. And then I told myself that I really needed to know that the repeating design motif of my pattern was truly buildable in lead---it is, as I have mentioned before, of a sufficiently small and picky scale that copper foil would for most people probably be the more natural choice here. And so I began leading.

If it all sounds like I may be experiencing a certain amount of impatience with regards to laminating and cutting my pattern, there might just be something to that. That's not the fun stuff. Leading is. Still, it's not all excuses and rationalizations here. There's definitely a bit of a learning curve going on as I fight my way through the leading of my first dogwood shape, especially since I'm working in lead with only a 1/8" face width around the flower: that leaves almost zero wiggle room for hiding mistakes. I'll want to lead in one of each of my problematic little circles (the light green dogwood centers and the red faceted jewels) before I consider myself to have walked through a successful and complete proof-of-concept, but it got late, and I have no idea how well the noise of my glass grinder may carry. Our neighbors live frightfully close; I may have mentioned before how I am sometimes awakened early in the morning by the sound of the neighbor lady sweet-talking her mildly neurotic Labrador retriever. Must address the camera situation soon. While doing a bit of web research to try to be able to quantify in precise technical terminology what I love about the big old broken camera and what I hate about the tiny less-old working camera, I discovered that the T.L.-O.W.C. has what's called a "fixed focus" lens, which is supposed to be result in more-or-less in-focus photos "from one meter to infinity." Aaaaand, there's my problem. For purposes of this here little weblog, having to take photos from a meter away is pretty much unacceptable. So whenever I break down and begin shopping for a new camera (ideally with a large pile of cash dropped by the gods from the sky for that exact purpose?), I will know to avoid that. It's a shame, though, in a way---I also learned that the fixed focus is a big part of why the little camera (Casio Exilim, second-generation) is so beautifully fast. The camera ex machina, thus, will necessarily have to be a slow(er) one. It's a lot like the primary rule of reasonable expectations that is much quoted by web developers and probably folks in many, many other professions: of Good, Fast, and Cheap, a client/consumer may ask for, and in fact receive, precisely two. Posted by Michelle at 10:55 PM

| Comments (0)

Wednesday, November 22, 2006: Jewels Ahoy

My jewels came. They're faceted, and so they're sparkly, and so they're unreasonably fun to play with. But they're also really tough to get a decent picture of with my one functioning camera.

Also in the photo is a little triangle of red glass left over from the crocus panel. I'll need to cut a whole pile of teeny little half-circles, half the size of my jewels, for the places in my design where red circles are cut off by the zinc frame. It's not that you can't cut the glass jewels---you can---it's that at their thickest points, they're a lot thicker than regular glass; they won't slide into the channel of the zinc framing. So I'll be using some leftover red cathedral glass in those places; the color match isn't 100% exact but those pieces will be so small that the mismatch will only be noticeable if you're looking. I also made some phone calls today to find out about replacing my IGU's. That's window-biz jargon (which I learned about twenty minutes ago) that stands for "insulated glass unit." You may recall, my existing IGUs are of recent vintage and in fine working order, but they have that pesky "decorative" grid between the two panes of glass that would end up showing through my stained glass panels and bugging me 'til the end of time. After some dead ends along the lines of "we have a 5-window minimum" and "we don't work in Silver Spring," I got in touch with a nice lady named Jennifer at Rockville's Bel Pre Glassworks, a company with a glass cutter incorporated into their logo, which made me smile because I'm a nerd. Jennifer was far more patient and helpful than I had any right to expect, given the scope of my itty-bitty two-window project. To order new IGUs, which I or my handy husband would need to install ourselves, she ballparked me a price of just under sixty-eight dollars a window for tempered safety glass, or just over forty-five for annealed glass, per. That's way less than I was afraid of; some prices I saw online for complete, DIY casement windows (including frames and sashes and other stuff I don't need) were in the $175 per window range and that wasn't going to fly. But if I can banish my grids for ninety bucks? Might just. Here's the fun part, though: to be absolutely 100% sure that what we order has the right measurements, the best thing to do is going to be to take our IGUs right out of their frames and take 'em up to Rockville to have a pro get all the dimensions. Doesn't look like that'd be hard---just a few screws---but see, it's about to be December out there (in fact, today's weather feels more January to me). And this time of year, you really want to have glass actually in your window frames. If I had the windows out of the frames for as little as an hour, I bet that'd be plenty time enough for it to get very, very cold in my living room. I guess some heavy-gauge contractor-style trash bags and duct tape might suffice for an afternoon, but those windows are on the side of the house facing the retired guy whose self-appointed job it is to police the lawn maintenance and general upkeep of every home on the block, and I think having trash-bag window panes, even temporarily, will send my poor neighbor right over the edge. I will have to consider the pet containment implications of having a couple of 14 by 32 inch holes in our living room wall, as well. Although I kind of wouldn't mind if one of the cats got out, if it were just long enough for them to realize "the warm's in the house, and the food's in the house: oh crap." Teach 'em a valuable lesson. Posted by Michelle at 03:07 PM

| Comments (1)

|

| Copyright © 2002-06 Michelle Kinsey Bruns. E-mail me at my first name at this domain. (Take that, spam spiders!)

|

||