|

|

|

|

I'm learning the art (or is it a craft?) of stained glass. At this weblog, I record progress, note useful links, and document flesh wounds. Links

The Art League

Weisser Glass Studio

Virginia Stained Glass Co.

Warner-Crivellaro

Glass Galleries Links List

The StoreFinder: Stained Glass Store Front

ArtGlassArt.com Tutorials

rec.crafts.glass

Nancy's Beginner Tips and Tricks

Splinter Removal Tips

Syndicate this site

Archives

By Date

November 2006 October 2006 May 2006 June 2004 October 2003 September 2003 August 2003 June 2003 May 2003 April 2003 March 2003 February 2003 January 2003 December 2002 November 2002 October 2002 September 2002 By Project Beaded Unity Candle Crocus Panel Dogwood Windows Green Tiered Lamp Lilypads/Lotus Panel Transoms Xmas Ornament |

|

Friday, November 01, 2002: Solder Soon

58 pieces leaded.

Took the photo above with a flash for a change, to try to show the colors better. It's still not exactly true but you get more of a feeling for it, anyway. You may notice that the frame of the panel---which is zinc channel, not lead; zinc offers a lot more support---is shorter than it needs to be (on the right), or cut with the miter corners in the wrong direction (on the top). One of those is due to bad planning, the other due to sheer duh on my part. I'll leave it to you to decide which is which. I did drive down to Springfield last Sunday to try to buy more zinc but they were out of my size. Which means I sat in Marine Corps Marathon traffic, troubled by inadvertent and persistent thoughts of another time the roads around the Pentagon were clotted with running people, for no good reason. Which does not mean I didn't buy anything while I was there. I'll try again this weekend. Hopefully I'll be done leading by Tuesday night's class so I can start soldering. Our instructor gave us a soldering demo last week, and uh, yeah, I'm scared of that. I'll get over it, though. A good thing is that with the lead technique, unlike with copper-foil, you only solder joints in the lead, not all around the edges of every single piece. So there's less for a newbie with a soldering iron to screw up. Totally random note: a jar of Mark Stay looks and feels exactly like a jar of ear wax. While this would no doubt impress our kitty Garfield tremendously, I am less than enthusiastic. Posted by Michelle at 06:14 PM

| Comments (0)

Friday, November 01, 2002: On Second Thought

On second thought, perhaps I will find myself without Friday-night plans and will finish leading my crocus panel instead.

Next to put on the other two sides of the zinc frame and to make sure all that is square, and then on to soldering. After that, puttying---shoving sticky glop underneath the face of the lead into the channels so that everything sets up nice and solid, as I understand. After that, patina the lead black. After that... who knows? Probably I'm missing something. The point: still a lot to do although it now looks so close to done. Posted by Michelle at 09:37 PM

| Comments (3)

Sunday, November 03, 2002: Breaking the Habit

For no one reason, I've been going to Virginia Stained Glass Company every time I needed supplies. It's easy to get to, but not fast to get to---there is no supply store that's near enough to where I live to be fast. My instructor works there one day a week, but I've only been in on that day once, and then he was teaching a class, so I just smiled in his direction and got someone else to help me. And the prices are okay, I guess, but they're no Warner-Crivellaro.

Yesterday I let my hair down and tried someplace new. Virginia Stained Glass was still out of my 3/8" zinc frame when I called, and I'm not known for my boundless patience, so it was off to Kensington, MD, and Weisser Glass Studio. It's tiny, but they have a lot of glass packed in there. So the size of the place doesn't seem to limit their selection much, however it does inhibit thorough glass-browsing, if there are other customers trying to do the same. Their workshop area in the back also appeared very small, although possibly there are more rooms I couldn't see that are not open to the public. There was a class going on while I was in the store; I wasn't into craning my neck to see how many people they'd crammed into the workshop but it couldn't have been many. Either that, or it was a very friendly class. At my own first class session back in September, our instructor handed out a list of stained-glass stores in the area and briefly touched on the unique characteristics of each; Weisser, he said, is offbeat and "funky." I can see it. I got a pretty good vibe from the place, and I got my zinc too. Flesh wound of the day: careless handling of a strip of zinc I'd just mitered left me with two parallel, razor-thin, stinging cuts on the inside of my right wrist. This does not hold a candle to Don's flesh wound of the day. It was to his right hand, incurred during the destruction of an old chain-link fence, and required a couple of hours of hanging around the E.R., five stitches, a tetanus shot, and an assload of antibiotics. See, I crack jokes about hurting myself for the sake of something to do on evenings and weekends, but compared to my sweetie, I'm just a rank amateur. Posted by Michelle at 11:28 AM

| Comments (0)

Sunday, November 03, 2002: Back to the Future

The National Park Service has a division called Heritage Preservation Services which "helps our nation's citizens and communities identify, evaluate, protect and preserve historic properties for future generations of Americans." They put out a series of publications called Preservation Tech Notes "intended for practitioners in the preservation field, including architects, contractors, and maintenance personnel, as well as for owners and developers seeking the preservation tax investment credit for rehabilitation." A few of these are online. One is entitled "Historic Glass: Repair and Reproduction of Prismatic Glass Transoms."

Introduced in the 1890s, prismatic glass transoms were a popular and practical means of directing daylight into building interiors. With origins in sidewalk vault lights and glass panels used on ship decks, prismatic tiles had ridges or other raised patterns on their inside surface that refracted sunlight toward the rear of a building. The pressed tiles were usually joined together with zinc or lead in a process similar to that used to create stained glass windows. An alternative, less common approach was to bond the tiles to copper strips during immersion in an electrolytic bath, a process known as electroglazing. At the peak of popularity, over a dozen manufacturers offered varying tile patterns - each "scientifically designed" to increase natural light levels and thereby reduce reliance upon light wells and artificial light sources. Prismatic glass tiles were used both in new construction and to update existing storefronts, until changing tastes and the dominance of electricity led to their functional obsolescence by the 1930s.

Really smart stuff. "The dominance of electricity" shows no signs of abating, but the world has come a long way in increased environmental consciousness since the 1930s, and I wonder if someone, somewhere, hasn't had the thought that prismatic transoms and windows are more energy-efficient than standard electric lighting and a hell of a lot lower-maintenance than solar-powered lighting of any kind. Posted by Michelle at 09:19 PM

| Comments (1)

Monday, November 04, 2002: The Wright Stuff

Last night's update was hastily concluded, when I realized that my sweetie and I were about to be late for a ten p.m. showing of The Ring. While detailed analysis of movie viewings is beyond the scope, as they say, of this website, let me just say that I wished we'd caught a matinee instead... daylight, even of the pallid early-wintry variety we've had so much of lately, would have been a sweet comfort, upon emerging from the theater.

So I picked "Publish" from the Post Status dropdown before I discovered who had originated prismatic glass transoms: none other than Frank Lloyd Wright, with a patent on prismatic glass tiles in 1897. His architectural genius is broadly acknowledged, but his contributions to art-glass design (or whichever term you prefer: stained glass, leaded glass, whatever) are less widely known amongst the general populace. He was the originator of the geometric and severe prairie-style stained-glass design, and in fact the terms "prairie style stained glass" and "Frank Lloyd Wright stained glass" are sometimes used interchangeably in the casual lingo of online stained-glass chats. Prairie glass transoms would be quite nearly period-perfect for our little 20's bungalow (as Don keeps reminding me)... unfortunately, it's not much to my taste. It's amazing, really, the blend of style and function that Frank Lloyd Wright brought to his work, particularly to something so seemingly simple as windows. To integrate art-glass windows into a building's design as a seamless part of its overall style, and to invent new ways to build windows so as to maximize the light taken for granted to shine through them: it seems to me that the man's fame was well-earned, indeed. Posted by Michelle at 03:40 PM

| Comments (8)

Tuesday, November 05, 2002: Home Stretch

I started soldering my crocus panel tonight at class, and finished one side.

Which means it's finally solid enough to hold vertically. Which means I can finally see what it looks like backlit.

Sadly enough, I've decided I don't like the colors. They are a bit much, and it turns out that the Cobalt Blue isn't anywhere close to the Dark Violet when you put it up to the light---the Dark Violet lets a lot more light through, which changes the color match considerably. But whatever. My first-ever work of stained glass was never going to be mistaken for high art. Also. There is a word for what my soldering work looks like, and that word is "ass." Again, I'm not too knotted up over it, one can't expect to be a genius with the soldering iron the first time one picks it up. But yick. Definitely thinking I'm going to patina the lead black; unless I'm wrong that would be matte black so my soldering clumsiness will be less glaringly obvious. For grins, here's what the panel looks like turned over:

Lastly: did I call it or did I call it? I burned myself tonight. Tried to pick up and flick away a little ball of solder which had dropped onto my glass and dried there, succeeded in doing so before realizing that the little ball of solder had not, in fact, actually dried yet. Now the very tip of my right index finger stings pretty emphatically. S'okay, though; just very recently my daily requirement for typed output has dropped way off. There are two class sessions left before my class is over. I think I may have someplace else to be Tuesday after next... so I'm going to try my best to finish up the panel next week. I'll solder the second side before the next class, then at class will do puttying and the one last step of "whiting" which basically consists of scrubbing the panel with chalk powder, reasons for which I did not catch. At that point I'll bring the panel home, leave it alone for a day or two to let the putty set up nice and solid, and then patina it in the basement. Our class doesn't cover patina work, so I'm on my own there. But slapping black goo over my lead with a cotton ball doesn't sound too tough. She said, with uncharacteristic optimism. After that? A copper-foil class as the first step toward working my way up to building lamps... and, at home, beginning design work on some transoms, before my sweetie puts me out of the house for failing to fulfill my home-improvement responsibilities. Posted by Michelle at 11:27 PM

| Comments (2)

Wednesday, November 06, 2002: Had To Happen Sooner or Later

Another milestone today: my first crack.

Sigh. It doesn't exist in the photos I took at the end of last night's class, so either it happened in transport on the way home, or it happened during today's ill-fated solder session. I had a hell of a time with it, and I don't know why. Particularly with the joints of lead came to the zinc framing: the solder would pool over on the zinc as if the lead had a force field around it. Plenty of solder flux, plus brand-new soldering iron: you tell me. Anyway, I have read that you can get cracks in your glass during soldering if you linger too long in one place with the hot iron. The radical shift in temperature---the soldering iron is 700 degrees F---can stress the glass and cause it to break. But I'd think I'd hear that---wouldn't I?---and too, the joints on either end of the break were pretty easy ones to solder. I also discovered, on the previously inaccessible back side of my panel, a dime-sized chip on the edge of another of my green pieces. It won't be very noticeable, visually speaking, but it is going to make me nervous forever... such places are excellent points for breakage at some point in the future, and the chip is big enough that I have a feeling that when or if the piece does break there, it won't be a nice neat hairline crack like the one in the photo above. I don't know. Too late to sweat these things now, for sure. I'm about 5/8 of the way through total soldering and there's no turning back now. Posted by Michelle at 05:25 PM

| Comments (3)

Thursday, November 07, 2002: Hurry Up and Wait

Finished soldering my crocus panel today. Now I have nothing more to do until my next (and almost certainly last) class on Tuesday, as I missed this week's puttying demo, due to horrible horrible rush-hour traffic in Alexandria... well, really due to the fact that I was having a tasty gumbo dinner at Southside 815, but I wouldn't have arrived at the restaurant late if it hadn't taken me forty-five minutes to crawl three miles of US-1. I tell you, cross the Potomac into Virginia and traffic just goes stupid. With a quickness.

I did manage not to crack anything today, and for whatever reason, my edge joints were considerably more well-behaved than they were yesterday. I'm sort of at a loss for proper cleaning, though... ammonia served to shine up my lead again, but no amount of Dawn nor Windex would remove the thin film of paste flux that now coats both sides of my entire project. A bad thing, as flux will eat into lead and cause oxidation over time, as I understand. I don't know how concerned I should be, but I imagine the thing won't fall apart before next Tuesday, so I'll ask my instructor then. Posted by Michelle at 03:04 PM

| Comments (0)

Sunday, November 10, 2002: Sic Gloria Transom

Now that the crocus panel is all but finished, it is time to turn my attention to the transoms in the hallway of the bungalow I share with my sweetie.

There are three in the center hallway downstairs, over doors to the bathroom, the guest room, and the dining room. Here's a "before" photo of the first two:

The other is across and down the hall so doesn't fit in the picture. But it's more of the same. There's also a transom over the back door in the kitchen, leading out to the mud room. It's sort of a mess---the last owners of the house, I believe, wanted to make sure that that transom would never open again, so its short ends are covered over outside with little ends of lumber, and then painted closed with a vengeance. Plus, there isn't a light in the mud room, so if that transom were replaced with pretty stained glass, the pretty stained glass would not be shown to its best advantage. So I might just skip that one entirely. I'll do the three in the hallway and see how I feel then. I dragged a bar stool up and down the hallway to stand on as I took measurements of each transom. In case I lose the scrap of paper on which all this data is recorded: 28 3/4" by 7 7/8" over the guest room and dining room; 26 3/4" by 7 7/8" over the bathroom; who the hell knows by 7 7/8" over the mud room. The transom in the bathroom was also painted shut. It took about twenty minutes of hacking with my five-in-one tool to finally loosen the transom so it would swivel freely, and I made the Devil's own mess doing it.

I was feeling awfully handy by the time I finished freeing the transom. I don't think it's swiveled on its pins in years and years. Now that I have good measurements, I'll bust out some graph paper and start making some drawings, see if I can come up with something my sweetie will like. It's the dreaded comp-approval phase of the project, except if this client gets too micromanagerial about the lovely transoms he'll be getting, pro bono no less, I can call him a finicky bastard, tell him to get lost and go cook me something nice for dinner. I sort of hope it happens, actually. Posted by Michelle at 03:48 PM

| Comments (0)

Monday, November 11, 2002: Ladies and Gentlemen, We Have a Winner

Fastest. Comp phase. Ever.

It started off as a freehand drawing and then was finished in Photoshop. Yes, I did take that Illustrator class last month, but I have not yet seen fit to actually spend four hundred dollars on the software, so. Challenges or experiments I have built into this project include: working with clear textured glass; using two widths of lead came (3/16" for on-purpose edges, 1/8" for "cut lines" where edges only exist for the purposes of making the project buildable); building with the intention of adding a wooden frame around the panels themselves; tweaking one design to create two end products differing in width by two inches; working with individual pieces up to 14" long; ordering glass sight-unseen from Warner-Crivellaro because Virginia Stained Glass had absolutely nothing that looked appealing for any of the colored glasses when I went scouting for materials today. The nice people at Spectrum Glass deserve a shoutout for putting big, photographic, eminently usable color chips of all their glass on their website. I've been swiping those images for use in defining Photoshop fill patterns, so all the glass colors/patterns in the image above really do exist... I'll just order what I used to do the comp, and quite likely learn a little something about their chips + my monitor vs. real life. A small gamble, but I like the colors I ended up with a lot, and I know that Spectrum glass is one of the easiest kinds to cut, so I'm sold. The best thing about this design? It's only 17 pieces. Times three is 51... which is still 18 pieces less than my crocus panel was. I'm hoping this means that construction will just fly by. You might think that simply shopping for glass would be an activity which would not result in flesh wounds. You would be wrong. I have two or three fresh hairline cuts on my right hand, incurred by just flipping through sheets of glass in the bins. Can't see em, but I sure can feel 'em. Posted by Michelle at 05:57 PM

| Comments (7)

Tuesday, November 12, 2002: Completion Pending Shouting

Class tonight was all about elbow grease and big messes.

First, soldering rings of wire onto the top back of the piece for hanging. I'm still a clumsy oaf with a soldering iron, which is why I'll show you a photo of the one my instructor did for me.

Second, puttying, which is taking a scrubbing-style brush that will never be usable again and using it to push sticky, clay-like putty into the channels of the lead on both sides of the piece.

Third, whiting, which is using another scrubbing-style brush to scrub the piece with, um, whiting, which helps remove excess putty around your seams and also polishes the glass and the lead.

Lastly, scrubbing the hell out of the thing with an old towel, which shines up the glass even more but causes the lead to lose its shine and go pewter-black. This happens with time anyway; as I understand it there is perpetual maintenance implied in trying to keep lead permanently shiny. Lots of straight ammonia, too. No thanks. I will be going to class for the last session next week after all, but only for about half an hour--- justlong enough to spot-patina my solder joints, which don't lose their shine when you polish them with a soft cloth the way the lead does. Right now my piece looks goofy, dark sedate lead put together with bright sparkly silver solder. After that? Hang the finished (!) panel up. Not in a window, but against a white wall, which will provide enough light from the rear to give the glass a little glow, but not enough to make me wince at the brightness of the green and the un-matched-ness of the blues that are apparent with full backlighting. There's a spot in the guest bedroom/office which will do nicely. The flesh wound of the evening was borne of sheer stupidity, which is another word for using your fingers instead of pliers to hold a tiny circle of metal wire while soldering it onto zinc. See also: clumsy oaf. What degree a burn is it again when it raises a fluid-filled blister? I bet you didn't even notice I typed this whole entry without once using the letters F, R, G, or V. Posted by Michelle at 10:41 PM

| Comments (0)

Wednesday, November 13, 2002: Buying Spree(s)

Yesterday I went to Weisser Glass Studio in Kensington again. It was mainly for one thing---1/2 inch zinc framing, of which Virginia Stained Glass seemed to be out, and which Warner-Crivellaro won't ship unless you order 12 of the six-foot strips. I thought that while I was there I'd also look to see if they might have any of the colored glasses I had picked out for my transoms. I was hoping, in particular, to get lucky with the green glass... I needed sheets at least 12.1 inches wide on one side, and anyplace I could find it online sold only up to twelve inches, give or take an eighth. So close yet so far.

Lo and behold, Weisser had everything I needed. Giant sheets of green glass, plenty of the red and orange too. Also the zinc. Also the lead. (I swear I have good reasons for having designed the transoms to take all different sizes of zinc and lead than any I happen to already have in the basement.) I said before that Weisser was tiny but jam-packed with a ton of glass. Must reiterate that sentiment now. I was very pleasantly surprised to find everything I needed there---I don't think that shop is fifteen feet wide, but wow. Between their glass selection and the fact that Virginia Stained Glass seems to be constantly out of several sizes of lead and zinc, I'm thinking it might be prudent to start hitting Kensington first instead of Springfield for my supplies from here on out. At the very least I'll be updating my sidebar over there. Momentous and historic, right? Forthwith, photos of all my glasses, including the clear sparkle glass, which I did buy at Virginia Stained Glass. The two sheets of clear and the one of green are all between two and three feet on all sides; it's sort of scary carrying around sheets of glass that big.

Posted by Michelle at 01:58 PM

| Comments (4)

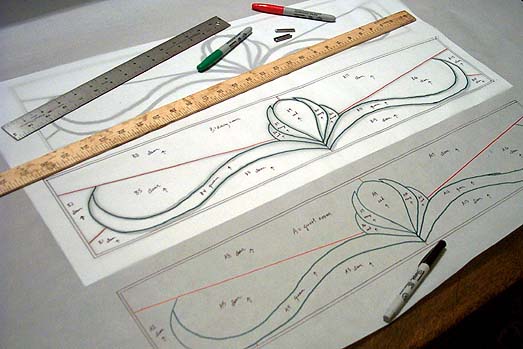

Thursday, November 14, 2002: Tracing Transoms

To Kinko's today, to output my transom patterns and then scale them up on the Oce oversize copier. Brought them home for tracing onto pattern paper, to find that one end of my Oce print sort of droops. The horizontal lines on the Oce print match up to the grid on the paper pattern just fine... until the last two or three inches when suddenly everything slopes down, ending up probably 3/16" off-kilter.

My instructor was saying weeks ago that he generally takes his patterns to a place that does blueprint copies for duplication, in case a "regular" photocopy should be off. "Gosh, that sounds like overkill," thought I. Another lesson learned. Having to compensate for the rogue slope makes it even more nervewracking than necessary to try to do two identical but separate traces of the same pattern. Also nervewracking is the need for maniacal lead-line precision with this piece; there's places where lead will abut lead, or lead will abut the zinc frame, which means more or less zero room for error in cutting the glass around those places. I wonder if there's a manufacturer of precision-tip permanent markers out there? Being able to draw in strokes the exact widths of 3/16" and 1/8" lead would make the fine-tuning much easier, if scarily encouraging of one's anal-retentive tendencies. And speaking of drawing in precision-width strokes, they are The Number One Reason Why Photoshop Is Clearly Inferior To Illustrator For Purposes Of Stained-Glass Patterns. I decided last night I wanted to change my Photoshop pattern file to reflect true widths of all my lead lines... bwahahah! For the keenly observant---if this looks like a pre-supplied excuse for failure ("It's Photoshop's fault, man!") if construction goes badly, that's because it is.

Posted by Michelle at 11:00 PM

| Comments (0)

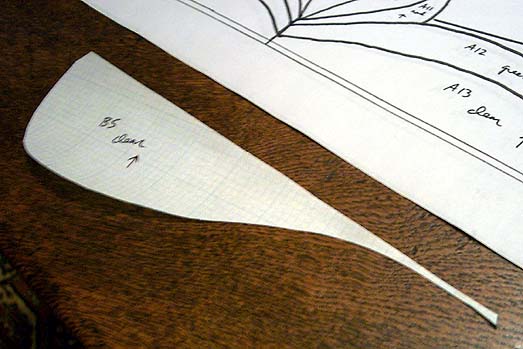

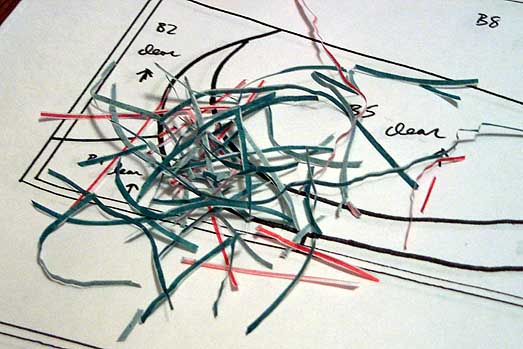

Saturday, November 16, 2002: Fun with Scissors

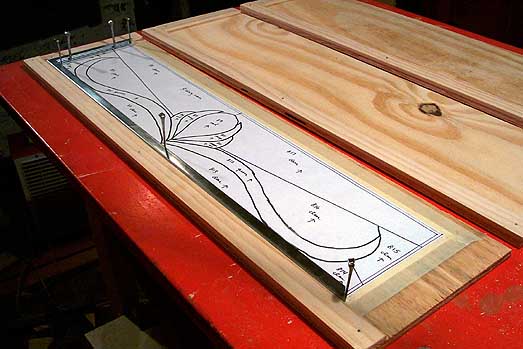

Cut up one of the patterns for my transoms today. Just one. It would be more efficient to build all three simultaneously, but until I know for sure that I can successfully cut and lead scary pieces like this---

---one transom at a time seems like a good idea. With the crocus panel project, I realized that it really is a good idea to try to cut precisely along the lines of your pattern. I had assumed that it wouldn't matter so much, as the pieces would fit together regardless. While that's true as far as it goes, it also means that building the piece on top of a building pattern is less of a help than it could be---optimally, you're using it to make sure your glass cuts are as they should be, which you really can't do if the lines on the building pattern bear no relation to where you cut your original pattern. Also, as it was my sad fortune to discover, if you end up breaking one of your glass pieces at some point, it's very useful to know that your building pattern will be pretty accurate for tracing out a replacement. So I cut up my pattern very slowly and very carefully tonight. My goal was to cut out with the pattern shears nothing but the red and green Sharpie lines which represented the edges of all my pieces. I am pleased with the results.

More building pattern inefficiencies: I took my original, pattern-paper pattern to a different Kinko's to use a different Oce oversize copier than I did to blow up my one-third-sized Photoshop comp the other day. You will remember that that first Oce introduced a slope in my nice straight lines at one end of my patterns. Well, there was no slope in the product from the Oce I used tonight, but it did give me a copy about 1/16" too long on the x axis, though the y was fine. For future work which needs to be installed into existing spaces, I'll definitely be looking into blueprint duplication so I don't have to deal with inaccuracies introduced by crappy Oce copying. ---Actually, Oce probably makes very fine machines, but experience tells me that anything you put into a Kinko's for public use is going to be beat to shit before long. I've got a crampy, stiff right hand today---must stop sleeping on top of my arm---so there's no way I was going to get any glass cut. But I did fit a building pattern and some zinc frame to one of my workboards, for which I bought wood earlier in the week, no thanks to those employees of Home Depot who apparently catch the short bus to work each morning. I must admit, it's sort of exciting to see the pattern all laid out on the workboard and ready to go. It looks like the real thing. Whatever that exactly means.

Posted by Michelle at 09:24 PM

| Comments (2)

Sunday, November 17, 2002: Not Exactly Helpless, But...

My right hand is still mysteriously aching, stiff, and all but useless. Painful activities include: shifting gears; writing; using a salt shaker; opening a car door; defending myself against tickling; spanking the Garfield cat (who is puzzled and disappointed that his daily allotment of ass-smacking has plummeted so dramatically). If I can't do any of that stuff, I definitely can't cut glass.

I have no idea how long this will last, but I do know I am right sick of it already. Don spent all evening playing in the basement workshop while, upstairs, I killed time that didn't want to die. It should have been both of us down there, making our respective messes of sawdust and glass shards, squabbling over power outlets and the good safety goggles. Damnit. *whine* Posted by Michelle at 08:53 PM

| Comments (6)

Tuesday, November 19, 2002: Patina On, Patina Off

My last class of the fall session at The Art League was tonight. I plan to return in January for the copper foil class so I can learn to make lamps. I shall not rest until I have built a kickass stained-glass lamp. Probably not then either.

All I had to do tonight was to apply patina to the solder joints and to the zinc frame of the crocus panel. The lead polishes down, so to speak, to a dark pewter-grey color, but the zinc and the solder remain shiny. That's what patina is for: to make everything a nice uniform color. In theory, anyway. It's tougher in practice. Particularly in cases like mine, with a zinc frame with a leaded piece---the two metals require differently composed patinas, and then the color match will never be perfect. I am not quite done with the patina work. My right hand still hurts if I use it a certain way, though not as much as it did. I thought the patina would be fluff work, i.e. non-painful, and it more or less was except for having to shine up the zinc with steel wool beforehand. That hurt, oh yes. So I didn't have it in me to finish everything tonight. I did patina all the inside solder joints---those that don't touch the zinc frame---and they turned out nicely. No more glaring silver solder joining up duller grey lead. And I did do the zinc patina. All that remains is to apply lead patina to the solder joints that meet the zinc... tomorrow, I think. You can see the difference between the shiny solder and the black zinc patina below.

The next, and last, photo you will see of the crocus panel will show it hanging over the bed in the guest bedroom. I suppose I should take a few moments to reflect on how nice it is to learn new things and have a creative outlet again and know how to make something, anything, with my own two hands... but I'm impatient to start building some transoms already, so the navelgazing will wait for some other time. Posted by Michelle at 09:19 PM

| Comments (2)

Friday, November 22, 2002: Crust and Crud

When I said the next photo of the crocus panel would be of it hanging up in the guest bedroom, I lied.

I've let the panel sit for three days after I did most of the patina work on Tuesday night. I still had some to do, but I've been sick---on top of my mystery hand injury, it turns out I've also had bronchitis for a month---and so I haven't been doing much of anything this week. When I headed down into the basement to take a look at what still needed done, I was aghast to spy all over the edges of my panel the dreaded "white mold" oxidation.

You can develop this oxidation on your finished piece if you haven't cleaned off the solder flux correctly. (Solder flux is what makes the solder actually stick to the metal; it comes in liquid, paste, or gel and generally you brush it along the places you'll be soldering.) I knew this already and thought I was prepared. I read up on every technique used for cleaning flux from stained glass and I used them all: ammonia or flux remover to neutralize the acid, oil-free liquid Dawn to remove the greasy reside, lots of hot water in all cases. However, looking back on all the time spent scrubbing the panel in the bathtub while ammonia fumes irritated my eyes, I realize I only really scrubbed the interior joints and glass---not the edge joints. As a result, I now have crusty oxidation outlining my solder where it lies on the zinc frame of the piece. Flux had collected there in those seams, and while I assume that the patina somehow reacted with the flux to speed oxidation, it would have happened with time even if I hadn't patinaed. So now I have to take fine steel wool and scrub all the patina from my zinc frame, then bust out the ammonia/flux remover/Dawn and go at the frame again. Maybe an old toothbrush will be the way to go. When that's done, I'll have to patina again. And when THAT'S done, maybe I'll really really be done with it. If you want to know the truth, I'm tired of the crocus panel... and if I didn't know that someday I'll want to be able to look back at my first piece and laugh at all its evident newbie-ness, I'd chuck the silly thing and be done with it. After all, I got what I wanted out of it: I learned how to do leaded stained glass. And I learned what not to do. Posted by Michelle at 07:12 PM

| Comments (4)

|

| Copyright © 2002-06 Michelle Kinsey Bruns. E-mail me at my first name at this domain. (Take that, spam spiders!)

|

||