|

|

|

|||

|

I'm learning the art (or is it a craft?) of stained glass. At this weblog, I record progress, note useful links, and document flesh wounds. Links

The Art League

Weisser Glass Studio

Virginia Stained Glass Co.

Warner-Crivellaro

Glass Galleries Links List

The StoreFinder: Stained Glass Store Front

ArtGlassArt.com Tutorials

rec.crafts.glass

Nancy's Beginner Tips and Tricks

Splinter Removal Tips

Syndicate this site

Archives

By Date

December 2006 November 2006 October 2006 May 2006 June 2004 October 2003 September 2003 August 2003 June 2003 May 2003 April 2003 March 2003 February 2003 January 2003 December 2002 November 2002 October 2002 September 2002 By Project Beaded Unity Candle Crocus Panel Dogwood Windows Green Tiered Lamp Lilypads/Lotus Panel Transoms Xmas Ornament |

|

Project Archive: Crocus Panel

This project was done for my first stained glass class, at the Art League in Alexandria, Virginia, during the Fall 2002 quarter. The project is an 18"x18" panel showing two blue/purple crocuses on a red background. I expect it to be finished the week of November 10, 2002. Friday, September 06, 2002: Birthday Present to Self

Today and yesterday, I took off work for my birthday. Everyone should take off work for their birthdays.

I went to the Art League School at the Torpedo Factory to try, yet again, to register for their stained glass classes. This is something I've been wanting to do for a year and a half now, but I've learned the classes fill up really fast. I thought I was registering early enough for the fall quarter by going in today, but no such luck: the Monday night class I wanted was full. I left them a check in case a spot opens up, or in case they open up an "overflow" class later on. I really would like to get in this quarter; my understanding is that they teach lead-came stained glass, as opposed to copper-foil, during the fall, and lead is what you'd want to do window type things with. Ever since I started talking about taking this class, Don has been dropping hints like boulders about doing some pretty transoms for the first floor of our house, and I guess that's a window type thing. We'll see. Fingers crossed. Posted by Michelle at 09:59 PM

| Comments (0)

Sunday, September 15, 2002: Registered for Class

Got a call from the Art League wanting to know if I was available for Tuesday night classes. I said yes, even while kissing goodbye another unscheduled weekday night---we're down to only Thursdays now. Oh well, all for a good cause. I'm excited.

Posted by Michelle at 05:59 PM

| Comments (0)

Tuesday, September 24, 2002: First Class Session

Had my first stained glass tonight. The instructor, Jimmy, seems really nice, and also seems to really know his stuff. He says he's been doing stained glass for 15 years and teaching for most of that time. It sounds like it's his living, between repair work and commissions (in that order), teaching, and working in a stained glass supply store one day a week.

Tonight was mostly talk. Which was fine, the extent of what I had known about stained glass can be summed up like this: "It's pretty." We did see some action toward the end of class, in the form of practice cutting and breaking on window glass. I won the "Golden Band-Aid Award" for drawing the first blood of the quarter, via an invisible glass splinter embedded in the ball of my thumb. Would that I had such success in the cutting itself: it seems that for me, applying enough pressure with the cutter to create a good score in the glass means I've got too much momentum to closely follow the pattern... or going slowly enough to closely follow the pattern means my score is much too weak, causing the glass to break incorrectly. I hope I'll get better; I felt somewhat discouraged by the time class was over.

We are to pick out or design patterns in time for next week's class. Says Jimmy: "Most of the stained glass supply stores around here know me as the guy who lets his beginners do whatever they want." I expect I'll be designing my own, which will be an additional challenge because this class does not cover design---but finishing something I designed myself will be twice as sweet as finishing a project out of my book. There are ten students in my class. Three of us are smokers, a phenomenal percentage in such a small group... perhaps it's simply an overlap in the danger-seeking demographic. While enjoying a getting-to-know-you cigarette outside, I told my new classmates about my high school wood shop class. Most everyone else chose for a project a clock fashioned out of a polished cross-slice of tree trunk. I chose a wall-hutch, with spindles and shelves and drawers. In short, it was way too much. The project never did get finished---I ended up moving away suddenly before the semester was over but I don't think I'd've gotten it done in time anyway---I believe I took an Incomplete for the class. That should have taught me a lesson about what reward an overachiever can expect... but I don't think I learned a thing. Posted by Michelle at 11:22 PM

| Comments (0)

Saturday, September 28, 2002: Ouch

That glass splinter I picked up Tuesday? Yeah... still there. In spite of my having soaked it in epsom salts and going at it with a needle. If I could have found the box of fresh blades for my X-acto knife, I'd've done that too. So now I have a chunk of glass and a hole in my thumb. You have no idea how much you use the ball of your thumb until it sends staggering bolts of pain up your forearm every time you do so. On the bright side, VH1 was showing The Godfather while all this was going on, which felt oddly thematically-appropriate.

Posted by Michelle at 11:34 PM

| Comments (0)

Monday, September 30, 2002: God Bless Photoshop

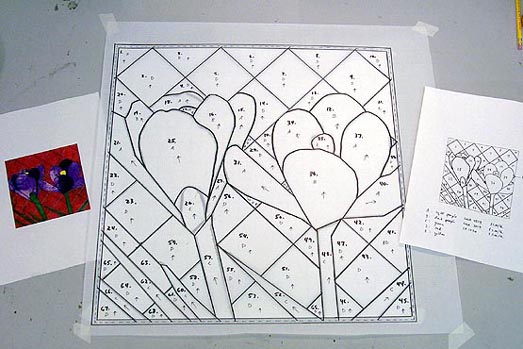

Pending a cutting-feasibility review from my instructor, this will be my lead-technique stained glass project for the quarter. I did it in Photoshop; very handy because I can have one layer for my color fills and another for the outlines and then just turn off the fill layer when it's time to print a cutting pattern. Fun trivia fact: "hot" colors of stained glass cost more per pound, because gold is what's used to achieve red tones in glass. It's my bad luck that I'm really, really fond of red.

In other news, my glass splinter seems to've worked itself out. Perhaps it simply needed some time to recover from the trauma of being chased around with a hot needle, I don't know. Posted by Michelle at 03:51 PM

| Comments (2)

Tuesday, October 01, 2002: Second Class Session

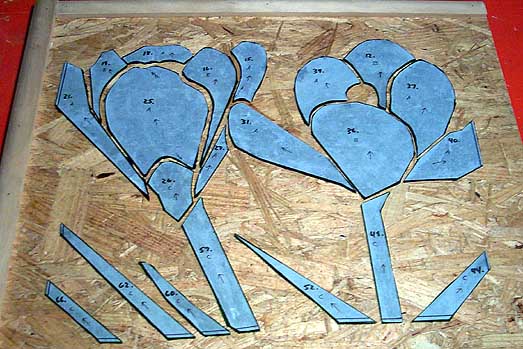

Tonight I finalized my pattern for my class project. My instructor recommended only one modification, which was to make somewhat shallower a sharp curve on a crucial piece of the project. "That's a big piece for you to have to try to cut a bunch of times," he said. "That's a money piece." You can see the modification in the photo below---to the biggest piece, number 25, of the flower on the left.

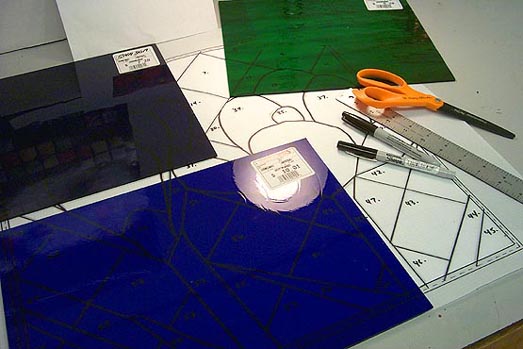

Oh, and I bought glass last weekend too.

Brands and colors are:

I had printed out my Photoshop design, then taken it to Kinko's to blow it up 400% on the Oce blueprint copier. The result of all that enlargement was pretty ugly, so tonight I traced it onto graph paper and will scrap the Oce print. I haven't started cutting my pattern yet, will do so after making an Oce print of the actual-size pattern. Am sort of reluctant to start cutting, the pattern is awfully neat and tidy just the way it is. Posted by Michelle at 11:26 PM

| Comments (0)

Saturday, October 05, 2002: Picked-Up Pieces

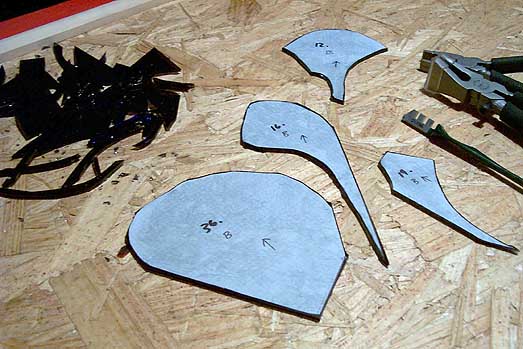

Cut up my pattern today. 69 pieces and it seemed to take forever. Can only imagine how long it will take to cut and grind every one of them.

Lori and Josh were over today, and they and Don sat and talked with me for a while, as I snipped. Lori asked a few questions about how all this stained-glass stuff works, and I, with the depth and breadth of encyclopedic knowledge which comes of the two whole class sessions under my belt, did my best to sound like I knew what I was talking about. Flesh wound du jour: loosened a flap of skin on my left thumb when my sheet of GNA Dark Violet slid through my hands and onto the floor. The distance it fell was not enough to break the glass, which is fortunate, because for whatever reason, the stained-glass supply place I went to last weekend had less of a selection of purples than of some other colors... as far as I know, I got the only piece of GNA Dark Violet they had in stock. The nice ladies at Virginia Stained Glass Co. say they can order more of most of their glasses, but I don't know how long that takes, and I believe I'm going to want to begin cutting this week. Also today, I went to Home Depot to buy plywood for a workboard, which is just a piece of cheap wood plus two raised strips along two sides to form an "L" shape into which you can build your stained-glass project, one piece at a time. I think you only do lead projects this way, not copper foil. Not really sure why but I think the instructor will start to show us construction methods on Tuesday so it'll all make sense then. Home Depot doesn't give me the same holy-shit-I-don't-belong-here feeling that I get in auto parts or sporting-goods stores, but I still generally feel like a poser there. Custom-cut squares of 7/16" ply and glossy red lipstick. Posted by Michelle at 08:56 PM

| Comments (0)

Tuesday, October 08, 2002: Let The Cutting Begin (Upon Something Other Than Myself)

Am pleased to report I'm feeling less useless with a glass cutter than I was at the first meeting of my stained glass class. Tonight, for a refresher, we started by hacking to death some more window glass, but I think we all quickly grew impatient with that, so the instructor showed us how to set up a pattern for cutting.

There are a few different methods of cutting glass to a pattern. The one we're learning is to actually cut up the paper pattern (called a 'cartoon,' I love that), then glue the pieces to sheets of stained glass, and cut around them. It must be one of the most time-consuming ways to do the job, but it also seems to me it'd be most precise.

Posted by Michelle at 11:52 PM

| Comments (3)

Wednesday, October 09, 2002: Homework

After taking some time to ponder my options, I decided that I needed to have a shop-vac ASAP so I could start doing some cutting at home. So after yet another trip to Home Depot, I came home and had my way with my Dark Violet glass. There were only four pieces to be done there, but very curvy ones, whereas most of the green pieces were all straight lines. Plus two of the Dark Violet pieces have shapes that end in long, skinny dagger-points, the cutting of which was giving me some trouble last night at class. No matter, things went well tonight, and even better, there is no bloodshed to report.

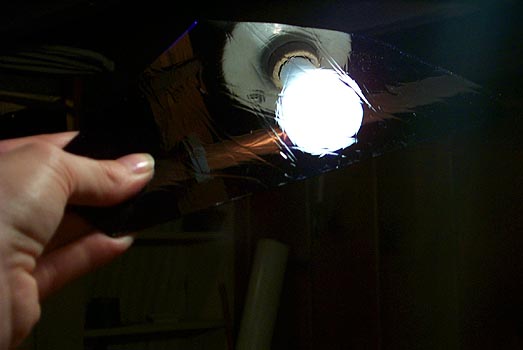

Below is a photo of my Dark Violet glass, reflecting a bare light bulb that hangs over the work bench area in the basement. You can see the texture of the glass here---have you ever dragged the tip of a butter knife through a pan of raw brownie mix, and watched a little indentation trail form in its wake? That's sort of what this glass looks like. Subtle, really neat.

Lastly, a bonus photo of Don wreaking havoc upon the living room using the blower attachment on his, I mean my, new toy:

Posted by Michelle at 11:43 PM

| Comments (3)

Thursday, October 10, 2002: Homework, the Sequel

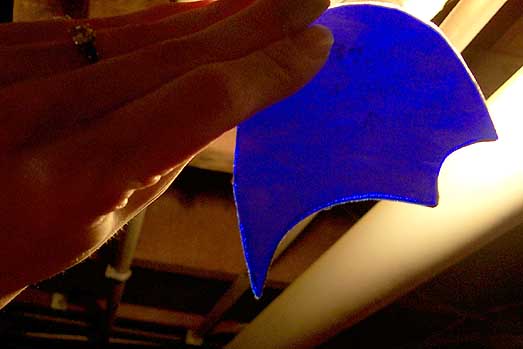

More cutting tonight. The Cobalt Blue pieces, nine of them. Wasn't sure I'd have enough glass, so I tried very hard to cut very carefully. Made it through eight and seven-eighths of those pieces before accidentally taking a small chip out of the back edge of piece number nine. I want so badly to pretend it didn't happen, but I can't: any chip, scratch, crack, or even too-rough edge becomes a stress point which will, two or six or twelve months down the road, be the first place the finished panel will crack.

Just for a moment, pretend with me that it didn't happen:

21 pieces down, 48 to go. That'll be 2 curvy small yellow bits, and 46 red background pieces, most of which are nothing but straight lines, i.e., harder for me to screw up. Plus, of course, a redo on the one I messed up tonight, whenever I can put my hands on a scrap-sized piece of Cobalt Blue. Tonight's injury: clumsily poked myself in the cuticle of the index finger of my left hand with a sharp corner of fresh-cut glass. That finger is looking really rough these days. Also today, ordered a grinder from Warner-Crivellaro. That price matching thing? They really mean it. I ended up with the sort of bargain you almost feel bad about. Almost. Posted by Michelle at 10:24 PM

| Comments (1)

Saturday, October 12, 2002: Please Mister Postman

Hovered over UPS's online tracking system today to see if I'd have my grinder in time to play with it over the weekend. The last line item on the tracking detail used to say that my package was in transit to Landover, Md., at 3:25 a.m. Late this afternoon, that line vanished. Now the last line is a "departure scan" from Lawnside, N.J. at 3:24. In other words: We know it left New Jersey, we just don't know which way it was headed.

[Midnight update: now the tracking detail doesn't show that it ever went anywhere. It's one line: "Billing information received." The hell? Don't make me feign surprise if UPS broke my shit and had to send it back where it came from.] Made a run this afternoon to Virginia Stained Glass Co., where I bought the smallest piece of GNA Cobalt Blue I could find. 10 inches by 10 inches. Not in the scrap bin. Seven dollars, because I got over-eager with the groziers and made a chip the diameter of the eraser on the end of a pencil. Sigh. The good news is, I also found a 6x6 square of a perfect Uroboros orangey-yellow, for my crocuses' pistils or stamens or whatever the hell they are. ("Genitalia," Don helpfully offers.) So I've got all my glass for the crocus panel... assuming I don't mis-break all my red into scrap. Posted by Michelle at 07:55 PM

| Comments (0)

Saturday, October 12, 2002: No, We Can't Still Be Friends

Apparently, the tenderness I feel for red glass is strictly unrequited. Red glass does not love me, and in fact, only tolerates me for the sake of maintaining social equilibrium among our mutual friends.

Maybe it's a Bullseye thing. Tonight was my first shot at cutting any glass of that brand and right from the start, the sheet was different from what I've played with before. The glass was textured on both sides: an unpleasant discovery. The conventional wisdom says to always make scores on the smooth side of the glass, so as to increase the chances of a break that follows your score line and not a ridge in the texture of the glass; I suppose I assumed that there would always be a smooth side. The sheet also had two rough, poured-looking edges instead of nice straight cuts. The rough edges were raised a bit, slightly thicker than the rest of the sheet, making difficult a good start to a score (you only get one shot, if a score is weak you can decide to break anyway and hope for the best, or call it a loss and work around it). And for whatever reason, I found it tough to start scores on this glass even on straight-cut edges... is it possible Bullseye glass is just, like, harder than Spectrum or GNA? Lastly, I was sufficiently unencumbered by clues to realize that the sheer size of this sheet of glass might call for a unique approach. Um, probably there are a lot of stained-glass craftspersons who would have no problem making a two-foot-long score on double-textured glass and then getting their running pliers to effect a nice straight two-foot-long break... but I'm not one of them yet. Baby steps, Michelle... baby steps. Fortunately, I eventually got a handle on things and stopped fantasizing about how nice my crocus panel would look with a background of clear, untextured window glass. In the end I cut fourteen red pieces, plus the redo on the problematic piece of Cobalt Blue from a couple nights ago. 35 pieces down, 34 to go. Ninety-four percent of the remaining cutting will be of the Bullseye red. Ugh ugh. The photo below, looking as it does a whole lot like most of the photos I've posted here to this point, is interesting for one reason only: my total-area ratio of cut pieces to scrap was way up tonight. (And would have been even more so had I not attempted that two-foot break, ending up with several only-partially-usable smaller chunks of glass.) Alas, the sudden improvement has more to do with my pattern than with my mad skillz: there were only two curved sides involved in tonight's 14 pieces, and everything else was straight lines. If I'd been working with a pattern that called for an equivalent amount of red, except curvy, I'd've cast away the evil bumpy red glass in favor of pillaging Don's basement stock of dusty window glass pretty damned quickly.

Posted by Michelle at 11:45 PM

| Comments (2)

Tuesday, October 15, 2002: Baby, I'm Ready To Go

At class tonight, I cut 22 pieces. 57 down, 12 to go. I was making good time, but what I made up for in speed I lacked in precision. Some pretty ugly edges, which means I didn't save any time at all, as I'll have to fix them on the grinder. I think I got impatient. A couple of the students in the class were ready to start assembling their panels, so the instructor showed us how to start building the pieces into the lead cames. He demonstrated with one of the students' panels and after he'd put together only three pieces you could really see how it would start to come together. So I want to be done with cutting so I can build too.

A bad precedent. I don't think that stained glass is really an appropriate hobby for the patience-impaired. Well, I'm in learning mode, ready to move on---at this point I'm pretty damned good at cutting. While chatting with the instructor tonight, I told him about the guilt-inducingly good deal I got on my grinder by taking advantage of Warner-Crivellaro's price match guarantee. He said that Warner is very much known for that, and that under no circumstances would it be a good idea to take their catalog with me to any stained-glass supply stores and stand around comparing prices. "The retail stores really hate Warner because of that whole price-matching thing." Today I received an email from a nice man named Bruce who is also new to stained glass. Bruce had some tips for me, plus his instructor's take on lightbox cutting as opposed to paper-pattern cutting, and was kind enough to give his permission for me to post his message here: Michelle, I came across your web page when doing a search for stained glass techniques. Thanks for the links you had, they helped a lot. Great weblog. You've certainly picked a challenging first piece. I'm also a stained glass newbie, had two classes so far, and I can really relate to many of the things you've written about! Our instructor, although initially taught the pattern/template method you are using, is now more of a free hand/pattern tracing aficionado, which is what he is teaching our class. He spends 4-5 hours a day (or more) cutting glass, and would not get nearly as much done if he had to cut templates for every piece. One of his real concerns with trying to cut with templates affixed to the glass (other than how time consuming it is) was if the cutter jumps onto the paper so you don't get a clean score all the way along your cut line. If he makes a template at all (for really opaque glass that doesn't work well with a light box), as often as not he will do so from scrap window glass directly over the pattern, and then trace around this with a black felt pen onto the opaque glass. I noticed from your pictures that you seem to be using straight type glass cutters. Have you considered a "pistol grip" type cutter? They much more comfortable to use, self oiling, and not much more expensive. You seem pretty serious about stained glass (not many newbies go and purchase grinders!), so you might consider at least trying out this kind of cutter. They're also a lot more durable then regular cutters. For you long straight lines, don't use your running pliers. Instead, put a long dowel (pencil diameter) under the glass directly under the score line, then press down on either side of the score line from above. It should snap cleanly right on the line. Also, you may want to tap under the score line with your cutter to extend a fissure along the score line first. Anyway, I'm looking forward to your continuing adventures! Cheers, Bruce. Posted by Michelle at 11:02 PM

| Comments (1)

Wednesday, October 16, 2002: Put Down the Glass Cutter and Step Away from the Workbench

I cut my last twelve pieces tonight.

Sapphireblue flexes Sapphireblue ripples I have some concern about the two or three very smallest ones. The tiniest is a triangle about half the size of the pink part of my pinkie fingernail. Depending on the face width of my lead cames, it might be covered entirely by lead and solder in the assembled panel, becoming an unsightly metallic glob. I can and probably should redesign away one of the tiny scraps (and I'm sure it will be a learning experience to try to do that at this stage in the game), but the smallest is just gonna have to be that glob. Coming soon: many hours hunched over a buzzing glass grinder, pausing every so often to check the bleeding at the very tips of my fingers and to wipe the collected film of flying glass dust from my plastic safety goggles. The glamour is so thick, you could cut it with a knife. Posted by Michelle at 10:57 PM

| Comments (0)

Thursday, October 17, 2002: Slave to the Grind

My pretty new grinder isn't so pretty or new any more.

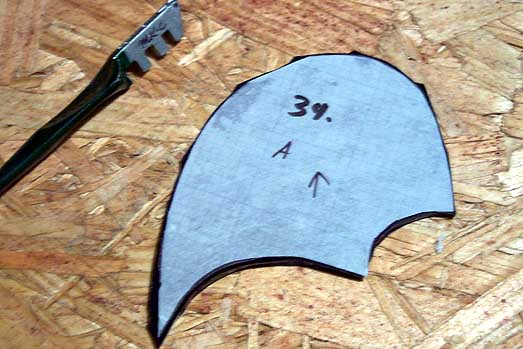

Remember that big piece with the pointy-cut convex edge?

I had at it with the grinder tonight...

... and now its edge is nicely un-pointy.

Issues with the grinder:

Bonus photo: all 69 cut pieces. 6 ground, 63 to go.

Posted by Michelle at 10:39 PM

| Comments (4)

Monday, October 21, 2002: Math I'd've Been Better Off Not Doing

Finished grinding all my edges on all my pieces tonight. There is one piece of green waterglass I will have to recut because the grinder chipped a tiny piece out of one corner. Not sure if maybe it was a bad cut to begin with, or maybe I caught the glass against the grinder head at an angle, or what.

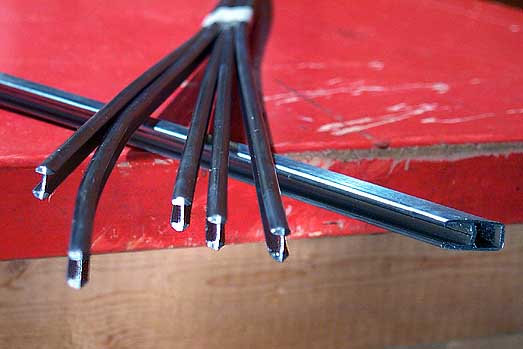

The lead cames I bought Friday night lurked ominously on the basement's cement floor, taunting me as I tried to grind good true edges, exactly to the edges of the glued paper templates. 5/32" face width minus 1/16" heart width divided by 2 sides of the "H" leaves me with a margin for error, in cutting and grinding, of forty-seven thousandths of an inch.

Posted by Michelle at 11:44 PM

| Comments (2)

Tuesday, October 22, 2002: Get the Lead Out

Busted ass Friday night and last night in order to get all my grinding done so I could begin leading tonight at class. There was no time over the weekend proper---among other things, our friends Kim and David got married in New York, so we took the train up to help them celebrate. Congratulations, you two, and many wishes for a long happy life together: if you can compromise on wedding-reception formal vs. jeans, you can get through anything.

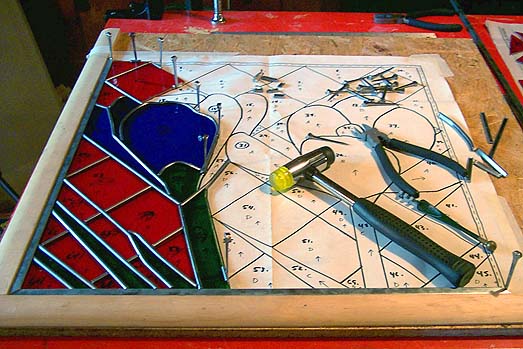

I finished the grinding last night at about eleven. Spent much of tonight's class washing templates and glue from my glass pieces. V-e-r-y s-l-o-w-l-y: one piece at a time so I could renumber each piece immediately, directly on the glass. Then I found out that the edge strips of wood on my workboard weren't square, which is what I get for just assuming that the schmoes at Home Depot can cut a straight line in plywood. So I managed to pry up one of the edge strips and its nails and re-assemble---without the benefit of a hammer, even. And then---and then---I started leading.

Incidental note: spotted a tiny jar of Mark Stay in my instructor's toolkit tonight. That answers that question. Posted by Michelle at 10:39 PM

| Comments (6)

Thursday, October 24, 2002: Eight Steps Forward, One Step Back

Leaded eight more pieces tonight.

Maybe I'll regret all the work I plan to have done by my next class session. Wouldn't it suck to walk in, show the instructor what I've done, and have him say, "That's great but that piece three rows in is all wrong, you need to take it apart to that point and redo"? Still, I won't be able to leave it alone for four whole nights. No way. Even though there's a couple of gaps at my joints which I know are pushing the acceptable limit. Unanswered questions of the night: If you have a lead line that's straight until it angles off at twenty degrees or so, is it advisable to bend your lead to fit, or to cut and fit two separate pieces? What if the angle is more than twenty degrees? And what's the best way to bend lead to achieve some degree of exactitude, especially with angles as opposed to soft curves? How much "wiggle," exactly, is permissible between pieces, to be filled in by solder later? Whose bright idea was it to design lead clippers that cut one side of the came in a straight line and the other in a 45-degree point? All this and more will have to wait for Tuesday. Something I did learn tonight: It's a good idea to restrict access to your glass workshop to people you really, really love. That way, when they fumble and break one of the pieces which you've already cut and ground, then soaked off and trashed its paper template, there's some chance they will survive to tell the tale. I'm not naming any names, but his URL is ratbastard.org. Posted by Michelle at 11:01 PM

| Comments (9)

Saturday, October 26, 2002: Bitch, Whine, and Moan

Leaded some more pieces last night and today. Dunno how many. I could count but I'm too cranky to bother. Here, you count:

Why cranky, you ask? It turns out that when that piece got fumbled and broken the other night, it hit and broke another piece on the way down. I didn't notice it til this afternoon. The piece that hit the floor isn't too difficult of a cut, so no big deal... the piece that stayed on the worktable waiting for me to notice it is going to be much more of a pain in the ass. If you squint real close at the above photo, maybe you can see which pieces were broken. Both of them are just to the right of the blue flower pieces that I've got leaded; both of them have their numbers circled on the building pattern. The piece that hit the floor is piece number 31, partially obscured by my mallet; it's just a wedge shape with one curved end, otherwise all straight lines. The piece that broke on the worktable is piece number 16, immediately adjacent to that big blue petal there. It's sort of like a crescent moon, stretched out to a long dagger point on the bottom end. Very curvy piece, and worse, it's got a huge inside (or concave) curve. These are the hardest lines to cut; you've got to take the curve out in a bunch of skinny, careful curving strips, one at a time, in order to make it work. On top of the difficulty of the cut, I'm going to have to take out a couple of the pieces I've already assembled in order to trace that piece from the building pattern. And any time you have to redo a cut without the original paper pattern piece, there is some risk of not ending up with precisely the same shape you got when you cut up your original pattern, depending on how closely you followed its lines. I know that when I was cutting my pattern, I wasn't 100% on the lines, but I thought it wouldn't matter too much, because with the pattern scissors that automatically remove 1/16" edges to allow for the lead cames, everything would fit together anyway. Now I know that that assumption only works for as long as you've got all your original paper pattern pieces. Mine, alas, are all landfill now. I will be much more careful to follow my pattern lines on my next project... but that doesn't help me today. All this is why I'm putting down the lead clippers and stepping away from the worktable. It's a sunny, warm day---the first we've had in D.C. since summer suddenly became winter a few weeks ago---maybe if I go outside and play, I will feel better. Or maybe it's just a way to put off tracing and recutting those damn petals. I don't even know if I have enough scrap Dark Violet and Cobalt Blue to redo them. I could go back downstairs now and look, I guess. But I won't. Posted by Michelle at 03:38 PM

| Comments (1)

Monday, October 28, 2002: Life, the Universe, and Everything

42 pieces leaded.

That includes one of the two pieces that were broken last week. In order to replace it, I traced its shape from the building pattern onto clear glass, cut and ground the clear glass to fit, then traced around that piece onto Dark Violet glass and cut and ground that. For the other piece that was broken, I have the clear piece cut and ground, but I think I'll see if I can shape the lead using the clear glass before cutting the stained glass. I'm finding that with curvy pieces, their fit may be altered by how closely you're able to curve the lead around them. With wavy or squiggly lines of multiple small curves especially, it's tough to make precise bends. The 42 pieces now in place also include two that just didn't fit right, so I recut them. One of those was due to the squiggly-lead factor above; the other was all straight lines so I'm attributing its bad fit to straightforward screw-up on my part, somewhere in the cutting or grinding process. I'd feel better about the progress I'm making if not for these three gaps:

Posted by Michelle at 10:18 PM

| Comments (5)

Tuesday, October 29, 2002: Devil in the Details

Had class tonight. Came in with 35 more pieces leaded than I had when I left the last class, and was subject to much gratifying oohing and aahing from classmates. Even the instructor seemed to approve. Go me.

I fixed one of my gaps tonight---the one where the edge of a red piece was refusing to slide snug into its channel---didn't even have to recut the piece, just did some grinding on the one I had. As for the other two, the instructor was optimistic about their hideability. One, he said could be filled with putty and covered over with lead joints without too much obvious fudging... and the other he said could be filled in by cutting a piece of came in half down the heart to make little lead plugs and soldering them into place. Just like Bruce said. Nice. There was little visible progress made, but it was good progress just the same. I spent a lot of time working on fitting a replacement for the second broken piece from last week. I think it was a good strategy to shape the lead using the clear piece, before tracing it to cut the Dark Violet glass. I actually did a pretty bang-up job tonight of figuring a way to create lead joints at a place where a the widest point of a curve sits right up against a straight line. The conventional wisdom for this kind of thing seems to be to use two separate strips of lead, side by side, for the line and for the curve, but just envisioning that, it sounds awfully vaguely-artistically-talented-kindergartener-with-no-real-sense-of-depth-or-perspective. So I opted to try to create the illusion of those two lines overlapping, by cutting the curve in two, cutting a bit of the heart from its lead, and trimming the face into a nice sharp point. I think it turned out pretty well, and will look even better once it's soldered. Removing some of the lead heart is proving to be a most useful trick. They say it makes for a weaker joint, but I don't know... it's going to be filled in with putty anyway, isn't it?

For those of you keeping track at home, I should now be all done having to replace broken pieces. I hope. It's so time-consuming to do all that tracing and checking and adjusting, over and over again. Also: not one, not two, but three flesh wounds tonight. One well-skinned knuckle when I slipped trying to stretch a too-short strip of lead, one medium-long cut to a finger due to careless handling of just-cut glass, and one instance of Mystery Injury, which wasn't there before I started helping clean up the classroom grinders but was bleeding pretty well when I was finished. Posted by Michelle at 11:59 PM

| Comments (0)

Friday, November 01, 2002: Solder Soon

58 pieces leaded.

Took the photo above with a flash for a change, to try to show the colors better. It's still not exactly true but you get more of a feeling for it, anyway. You may notice that the frame of the panel---which is zinc channel, not lead; zinc offers a lot more support---is shorter than it needs to be (on the right), or cut with the miter corners in the wrong direction (on the top). One of those is due to bad planning, the other due to sheer duh on my part. I'll leave it to you to decide which is which. I did drive down to Springfield last Sunday to try to buy more zinc but they were out of my size. Which means I sat in Marine Corps Marathon traffic, troubled by inadvertent and persistent thoughts of another time the roads around the Pentagon were clotted with running people, for no good reason. Which does not mean I didn't buy anything while I was there. I'll try again this weekend. Hopefully I'll be done leading by Tuesday night's class so I can start soldering. Our instructor gave us a soldering demo last week, and uh, yeah, I'm scared of that. I'll get over it, though. A good thing is that with the lead technique, unlike with copper-foil, you only solder joints in the lead, not all around the edges of every single piece. So there's less for a newbie with a soldering iron to screw up. Totally random note: a jar of Mark Stay looks and feels exactly like a jar of ear wax. While this would no doubt impress our kitty Garfield tremendously, I am less than enthusiastic. Posted by Michelle at 06:14 PM

| Comments (0)

Friday, November 01, 2002: On Second Thought

On second thought, perhaps I will find myself without Friday-night plans and will finish leading my crocus panel instead.

Next to put on the other two sides of the zinc frame and to make sure all that is square, and then on to soldering. After that, puttying---shoving sticky glop underneath the face of the lead into the channels so that everything sets up nice and solid, as I understand. After that, patina the lead black. After that... who knows? Probably I'm missing something. The point: still a lot to do although it now looks so close to done. Posted by Michelle at 09:37 PM

| Comments (3)

Tuesday, November 05, 2002: Home Stretch

I started soldering my crocus panel tonight at class, and finished one side.

Which means it's finally solid enough to hold vertically. Which means I can finally see what it looks like backlit.

Sadly enough, I've decided I don't like the colors. They are a bit much, and it turns out that the Cobalt Blue isn't anywhere close to the Dark Violet when you put it up to the light---the Dark Violet lets a lot more light through, which changes the color match considerably. But whatever. My first-ever work of stained glass was never going to be mistaken for high art. Also. There is a word for what my soldering work looks like, and that word is "ass." Again, I'm not too knotted up over it, one can't expect to be a genius with the soldering iron the first time one picks it up. But yick. Definitely thinking I'm going to patina the lead black; unless I'm wrong that would be matte black so my soldering clumsiness will be less glaringly obvious. For grins, here's what the panel looks like turned over:

Lastly: did I call it or did I call it? I burned myself tonight. Tried to pick up and flick away a little ball of solder which had dropped onto my glass and dried there, succeeded in doing so before realizing that the little ball of solder had not, in fact, actually dried yet. Now the very tip of my right index finger stings pretty emphatically. S'okay, though; just very recently my daily requirement for typed output has dropped way off. There are two class sessions left before my class is over. I think I may have someplace else to be Tuesday after next... so I'm going to try my best to finish up the panel next week. I'll solder the second side before the next class, then at class will do puttying and the one last step of "whiting" which basically consists of scrubbing the panel with chalk powder, reasons for which I did not catch. At that point I'll bring the panel home, leave it alone for a day or two to let the putty set up nice and solid, and then patina it in the basement. Our class doesn't cover patina work, so I'm on my own there. But slapping black goo over my lead with a cotton ball doesn't sound too tough. She said, with uncharacteristic optimism. After that? A copper-foil class as the first step toward working my way up to building lamps... and, at home, beginning design work on some transoms, before my sweetie puts me out of the house for failing to fulfill my home-improvement responsibilities. Posted by Michelle at 11:27 PM

| Comments (2)

Wednesday, November 06, 2002: Had To Happen Sooner or Later

Another milestone today: my first crack.

Sigh. It doesn't exist in the photos I took at the end of last night's class, so either it happened in transport on the way home, or it happened during today's ill-fated solder session. I had a hell of a time with it, and I don't know why. Particularly with the joints of lead came to the zinc framing: the solder would pool over on the zinc as if the lead had a force field around it. Plenty of solder flux, plus brand-new soldering iron: you tell me. Anyway, I have read that you can get cracks in your glass during soldering if you linger too long in one place with the hot iron. The radical shift in temperature---the soldering iron is 700 degrees F---can stress the glass and cause it to break. But I'd think I'd hear that---wouldn't I?---and too, the joints on either end of the break were pretty easy ones to solder. I also discovered, on the previously inaccessible back side of my panel, a dime-sized chip on the edge of another of my green pieces. It won't be very noticeable, visually speaking, but it is going to make me nervous forever... such places are excellent points for breakage at some point in the future, and the chip is big enough that I have a feeling that when or if the piece does break there, it won't be a nice neat hairline crack like the one in the photo above. I don't know. Too late to sweat these things now, for sure. I'm about 5/8 of the way through total soldering and there's no turning back now. Posted by Michelle at 05:25 PM

| Comments (3)

Thursday, November 07, 2002: Hurry Up and Wait

Finished soldering my crocus panel today. Now I have nothing more to do until my next (and almost certainly last) class on Tuesday, as I missed this week's puttying demo, due to horrible horrible rush-hour traffic in Alexandria... well, really due to the fact that I was having a tasty gumbo dinner at Southside 815, but I wouldn't have arrived at the restaurant late if it hadn't taken me forty-five minutes to crawl three miles of US-1. I tell you, cross the Potomac into Virginia and traffic just goes stupid. With a quickness.

I did manage not to crack anything today, and for whatever reason, my edge joints were considerably more well-behaved than they were yesterday. I'm sort of at a loss for proper cleaning, though... ammonia served to shine up my lead again, but no amount of Dawn nor Windex would remove the thin film of paste flux that now coats both sides of my entire project. A bad thing, as flux will eat into lead and cause oxidation over time, as I understand. I don't know how concerned I should be, but I imagine the thing won't fall apart before next Tuesday, so I'll ask my instructor then. Posted by Michelle at 03:04 PM

| Comments (0)

Tuesday, November 12, 2002: Completion Pending Shouting

Class tonight was all about elbow grease and big messes.

First, soldering rings of wire onto the top back of the piece for hanging. I'm still a clumsy oaf with a soldering iron, which is why I'll show you a photo of the one my instructor did for me.

Second, puttying, which is taking a scrubbing-style brush that will never be usable again and using it to push sticky, clay-like putty into the channels of the lead on both sides of the piece.

Third, whiting, which is using another scrubbing-style brush to scrub the piece with, um, whiting, which helps remove excess putty around your seams and also polishes the glass and the lead.

Lastly, scrubbing the hell out of the thing with an old towel, which shines up the glass even more but causes the lead to lose its shine and go pewter-black. This happens with time anyway; as I understand it there is perpetual maintenance implied in trying to keep lead permanently shiny. Lots of straight ammonia, too. No thanks. I will be going to class for the last session next week after all, but only for about half an hour--- justlong enough to spot-patina my solder joints, which don't lose their shine when you polish them with a soft cloth the way the lead does. Right now my piece looks goofy, dark sedate lead put together with bright sparkly silver solder. After that? Hang the finished (!) panel up. Not in a window, but against a white wall, which will provide enough light from the rear to give the glass a little glow, but not enough to make me wince at the brightness of the green and the un-matched-ness of the blues that are apparent with full backlighting. There's a spot in the guest bedroom/office which will do nicely. The flesh wound of the evening was borne of sheer stupidity, which is another word for using your fingers instead of pliers to hold a tiny circle of metal wire while soldering it onto zinc. See also: clumsy oaf. What degree a burn is it again when it raises a fluid-filled blister? I bet you didn't even notice I typed this whole entry without once using the letters F, R, G, or V. Posted by Michelle at 10:41 PM

| Comments (0)

Tuesday, November 19, 2002: Patina On, Patina Off

My last class of the fall session at The Art League was tonight. I plan to return in January for the copper foil class so I can learn to make lamps. I shall not rest until I have built a kickass stained-glass lamp. Probably not then either.

All I had to do tonight was to apply patina to the solder joints and to the zinc frame of the crocus panel. The lead polishes down, so to speak, to a dark pewter-grey color, but the zinc and the solder remain shiny. That's what patina is for: to make everything a nice uniform color. In theory, anyway. It's tougher in practice. Particularly in cases like mine, with a zinc frame with a leaded piece---the two metals require differently composed patinas, and then the color match will never be perfect. I am not quite done with the patina work. My right hand still hurts if I use it a certain way, though not as much as it did. I thought the patina would be fluff work, i.e. non-painful, and it more or less was except for having to shine up the zinc with steel wool beforehand. That hurt, oh yes. So I didn't have it in me to finish everything tonight. I did patina all the inside solder joints---those that don't touch the zinc frame---and they turned out nicely. No more glaring silver solder joining up duller grey lead. And I did do the zinc patina. All that remains is to apply lead patina to the solder joints that meet the zinc... tomorrow, I think. You can see the difference between the shiny solder and the black zinc patina below.

The next, and last, photo you will see of the crocus panel will show it hanging over the bed in the guest bedroom. I suppose I should take a few moments to reflect on how nice it is to learn new things and have a creative outlet again and know how to make something, anything, with my own two hands... but I'm impatient to start building some transoms already, so the navelgazing will wait for some other time. Posted by Michelle at 09:19 PM

| Comments (2)

Friday, November 22, 2002: Crust and Crud

When I said the next photo of the crocus panel would be of it hanging up in the guest bedroom, I lied.

I've let the panel sit for three days after I did most of the patina work on Tuesday night. I still had some to do, but I've been sick---on top of my mystery hand injury, it turns out I've also had bronchitis for a month---and so I haven't been doing much of anything this week. When I headed down into the basement to take a look at what still needed done, I was aghast to spy all over the edges of my panel the dreaded "white mold" oxidation.

You can develop this oxidation on your finished piece if you haven't cleaned off the solder flux correctly. (Solder flux is what makes the solder actually stick to the metal; it comes in liquid, paste, or gel and generally you brush it along the places you'll be soldering.) I knew this already and thought I was prepared. I read up on every technique used for cleaning flux from stained glass and I used them all: ammonia or flux remover to neutralize the acid, oil-free liquid Dawn to remove the greasy reside, lots of hot water in all cases. However, looking back on all the time spent scrubbing the panel in the bathtub while ammonia fumes irritated my eyes, I realize I only really scrubbed the interior joints and glass---not the edge joints. As a result, I now have crusty oxidation outlining my solder where it lies on the zinc frame of the piece. Flux had collected there in those seams, and while I assume that the patina somehow reacted with the flux to speed oxidation, it would have happened with time even if I hadn't patinaed. So now I have to take fine steel wool and scrub all the patina from my zinc frame, then bust out the ammonia/flux remover/Dawn and go at the frame again. Maybe an old toothbrush will be the way to go. When that's done, I'll have to patina again. And when THAT'S done, maybe I'll really really be done with it. If you want to know the truth, I'm tired of the crocus panel... and if I didn't know that someday I'll want to be able to look back at my first piece and laugh at all its evident newbie-ness, I'd chuck the silly thing and be done with it. After all, I got what I wanted out of it: I learned how to do leaded stained glass. And I learned what not to do. Posted by Michelle at 07:12 PM

| Comments (4)

|

|||

| Copyright © 2002-06 Michelle Kinsey Bruns. E-mail me at my first name at this domain. (Take that, spam spiders!)

|

|||||