|

|

|

|

I'm learning the art (or is it a craft?) of stained glass. At this weblog, I record progress, note useful links, and document flesh wounds. Links

The Art League

Weisser Glass Studio

Virginia Stained Glass Co.

Warner-Crivellaro

Glass Galleries Links List

The StoreFinder: Stained Glass Store Front

ArtGlassArt.com Tutorials

rec.crafts.glass

Nancy's Beginner Tips and Tricks

Splinter Removal Tips

Syndicate this site

Archives

By Date

November 2006 October 2006 May 2006 June 2004 October 2003 September 2003 August 2003 June 2003 May 2003 April 2003 March 2003 February 2003 January 2003 December 2002 November 2002 October 2002 September 2002 By Project Beaded Unity Candle Crocus Panel Dogwood Windows Green Tiered Lamp Lilypads/Lotus Panel Transoms Xmas Ornament |

|

December 09, 2002: Back in the Saddle Again

After having taken most of a couple weeks off from stained glass and pretty much everything else, due to bronchitis and sinus infection, a mysterious hand injury, a cold basement, and a giant pile of fence pickets (courtesy Don) blocking my access to the workbench, I put my copy of The John Lennon Collection on the stereo, cranked it up, and got back to work today. I've cut 14 of 17 pieces of one transom, and touched up 11 of those with the grinder. A lovely thing about this design is that it's horizontally symmetrical, so I can flip my pieces over so as to see the glass rather than the bits of pattern paper stuck to them, and still have them fit (more or less) on my building pattern.

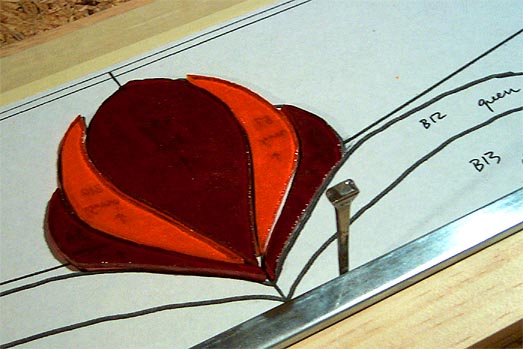

I have been using correspondent Bruce's dowel trick for breaking very long straight lines in glass. Works like a charm, and I'm glad he shared it with me. Besides being very effective at keeping the break on the score, it's also a hell of a lot safer to break a big piece of glass when it's lying flat than it would be to do it with running pliers. I'm not having so much luck with tapping. It's said you can control a tough break by first scoring as normal, then turning the glass over and tapping the end of a glass cutter on the underside of the the score to create and then slowly extend a crack along the score line. I've tried it once, on a score too long to trust to running pliers, too far from the edge of the glass to use breaking pliers, and too curvy to rest atop a dowel. My result was a nasty crack through the middle of my piece, which necessitated slow and careful scraping of the pattern piece from the glass using an X-acto knife. Which is SUCH a pain in the ass, takes forever to get it off the glass intact. Grunt work, and the best argument I can think of for cutting glass by tracing it out on a lightbox instead of using paper patterns. My deep dark secret is that I'm not 100% sure my transoms are buildable as I have designed them. Well---not by me, anyway. The first challenge in my pattern is that the orange pieces of the flower-shape sort of notch into the clear glass at their tops, a little bit. It's a challenge because you wouldn't be able to cut a notch out of a piece of glass without breaking it---unless you had four hundred bucks to drop on a ring saw---so I'm relying on the 1/4" supplementary head of my Glastar SuperStar II grinder to create a little notch for the glass to slide into. Just due to the nature of the tool, it won't be able to do exactly what I have designed into my pattern, so some on-the-fly fitting will be required once I get to the point of leading everything. Should be fun. Here's hoping I can make it work. The 1/4" grinder head was a little scary to use for the first time today. I set up my mini table so I had a support surface for my glass at the height of the 1/4" head, and all that worked fine, but when I actually started using it, the grinder head seemed loose. It wiggled some, and too much pressure on the glass against the head would cause the head to try to sort of grab the glass and shoot it at me. When I stopped and removed the mini table, I found that a tiny sort of screw which holds the 1/4" head to the top of the 3/4" head had loosened to the point of falling out when I lifted the 1/4" head. I cannot imagine how. Vibrations from the grinder, maybe? But that's what a grinder does, is vibrate. I'll have to keep an eye on that little screw. Projectile grinder heads are not one of the risks I bargained for when signing up for this little hobby of mine. A very merry Christmas And a happy New Year Let's hope it's a good one Without any fear Posted by Michelle on December 09, 2002 08:37 PM Comments

And that's what happens when your hands slip off the shift key, onto the return key. Sorry about the empty comment. Good to see you back at the transoms! Posted by: Adrith on December 10, 2002 10:10 AMComments are closed. Contact me via the email address at the bottom of the blog pages.

|

| Copyright © 2002-06 Michelle Kinsey Bruns. E-mail me at my first name at this domain. (Take that, spam spiders!)

|

||