|

|

|

|

I'm learning the art (or is it a craft?) of stained glass. At this weblog, I record progress, note useful links, and document flesh wounds. Links

The Art League

Weisser Glass Studio

Virginia Stained Glass Co.

Warner-Crivellaro

Glass Galleries Links List

The StoreFinder: Stained Glass Store Front

ArtGlassArt.com Tutorials

rec.crafts.glass

Nancy's Beginner Tips and Tricks

Splinter Removal Tips

Syndicate this site

Archives

By Date

November 2006 October 2006 May 2006 June 2004 October 2003 September 2003 August 2003 June 2003 May 2003 April 2003 March 2003 February 2003 January 2003 December 2002 November 2002 October 2002 September 2002 By Project Beaded Unity Candle Crocus Panel Dogwood Windows Green Tiered Lamp Lilypads/Lotus Panel Transoms Xmas Ornament |

|

December 13, 2002: Pictures Can Lie, and Do

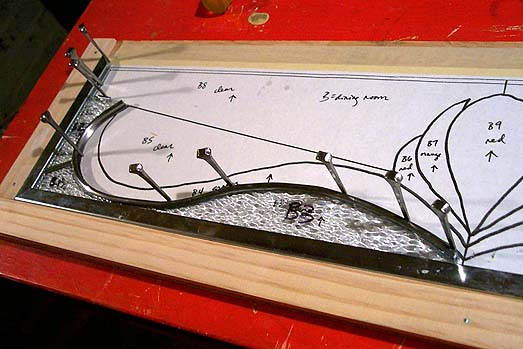

You might think, from the photograph below, that I had gotten off to a good start in leading my first transom.

You would be wrong. Turns out that the green S-shaped piece that slides in next to and above the three clear pieces in the photograph is a bit too S-shaped to really want to slide in there properly. It was (is, will be) tough to slide the S-shaped piece firmly into its slot, because its shape and the shape of its neighbors means I can't just slide it in from the side or from above, in one smooth motion. Really I think that instead of fixing in place one piece at a time, from the lower-left corner of the panel inward, I'm going to have to sort of puzzle the first four pieces together as a discrete unit and then fix that into the corner of my workboard. As far as I can tell, such a trick would require me to have about five hands, but I'll worry about that later. I resigned myself to this eventuality only after a lot of futile pushing of glass and bending of lead which resulted in my breaking piece B3, the widest clear piece pictured above, across its skinny panhandle, where the piece is almost entirely swallowed by the channel of the zinc frame. There is some optimism to be had, however: unlike with my last (first) panel, when I soaked the pattern pieces off my cut glass, I did it so that they could be removed in one piece. Three cheers for pattern paper with a waxy, somewhat water-resistant coating. So at least I still have my original pattern piece for re-cutting. Far preferable to having to trace out a piece from a building pattern the accuracy of which was suspect from the start. I'm going to have to figure out how to bend lead to fit a curvy piece of glass without putting undue pressure on the glass itself. That's how I broke B3 up there, and I broke a piece of glass on my crocus panel that way too (though not so noticeably that I didn't just pretend it didn't happen and keep on with the leading). A big challenge. If I knew how to work a jigsaw, I could perhaps create a wooden template in the shape of a curvy glass piece, and bend the lead around its edges. I mean, it'd be a pretty high-maintenance solution, but worth it maybe for glass pieces so skinny or so curvy that bending lead around them is just asking for trouble. Or maybe I should just stick to 5/32" lead until I'm better at all this. My plan for the transoms is to use 1/8" lead for the cut lines and 3/16" lead for the lines of the design proper. Those sizes are only 1/32" smaller and larger, respectively, than the lead I used in the crocus panel, but the difference in the way it feels is huge. The 1/8" lead is so soft that (I know now) it's possible to actually break it while stretching it out, and so soft that once it's stretched it keeps wanting to bend again; the 3/16" lead is harder to cut and harder to bend and probably contributed to tonight's problems. I need to keep in mind that I'm still a huge newbie, that this is only my second piece, that to get discouraged at this stage would be basically pretty arrogant. All the differences between the crocus panel and the transoms make for a lot of room for mistakes, but each one adds something to my knowledge of stained-glass construction. That's what I'm telling myself. In between telling myself, "Self, you're such a clumsy cow." Speaking of. I got through cutting and grinding all my glass without too much bloodshed, but for some reason I kept spouting tiny crimson leaks from my hands tonight when I wasn't looking. They were all such superficial wounds that there was no pain---the issue instead is, when you're working with the lead came, you can see black lead residue rubbing off on your hands. It looks like newsprint smudged onto your palms after a studious read of a fat Sunday edition. Generally it can be washed off without a problem... but when your hands are both sooty with lead and dotted with bleeding nicks, you do begin to feel a little bit of concern for your long-term health. Posted by Michelle on December 13, 2002 09:39 PM Comments

Comments are closed. Contact me via the email address at the bottom of the blog pages.

|

| Copyright © 2002-06 Michelle Kinsey Bruns. E-mail me at my first name at this domain. (Take that, spam spiders!)

|

||